- PROCESS PLANT OPERATORS

- INDUSTRIAL MAINTENANCE

- COMMUNITY COLLEGES

HYDRAULIC CIRCUIT TRAINING COURSE - CBT / WBT

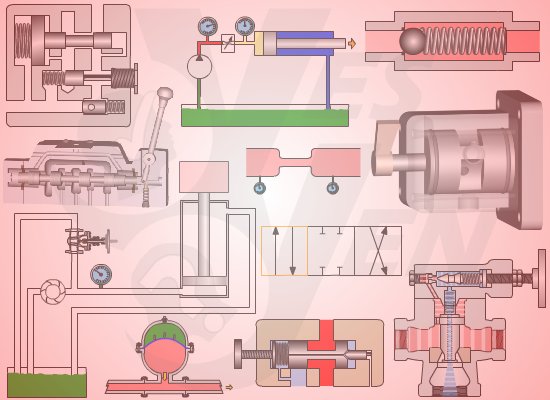

The Training Course on Industrial Hydraulics has been developed to understand the Basic Hydraulic Working Principle and the various Components used in a Hydraulic Circuit. The course, designed with extensive Graphics and Hydraulic Animation, gives a very clear and detailed knowledge on the subject.

Click above 'image' for Animated Demo/Guided Tour of the Hydraulics

Training Course which focuses on Graphics, Animation and Step-by-Step Learning

INDUSTRIAL HYDRAULICS - A FEW HIGLIGHTS

- In-depth coverage on Hydraulic-principles

- Detailed description of Components and working

- Build-up of a circuit with two jobs

- Extensive 2D / 3D Graphics, Models and Animations

- Skill tests, Certificate printouts.

The Industrial Hydraulic Training Course covers Hydraulic Basics / Principles and Hydraulic Components in Explicit detail. The primary focus on Hydraulic Component and Hydraulic Circuit Animation / Graphics helps in very clearly understanding Hydraulic Operating and Working Principles.

The CBT provides detailed knowledge on various components like Hydraulic Pumps, Actuators (Cylinders / Rotary Motors), Directional Valves, Servo Valves, Flow Control (Pressure / Temperature Compensation) Valves, Pressure Control Valves, etc.

The Industrial Hydraulic Training Program has a dedicated module that builds up a basic Hydraulic Circuit and gives an in-depth understanding on the relevance and co-ordination of the various Hydraulic Components.

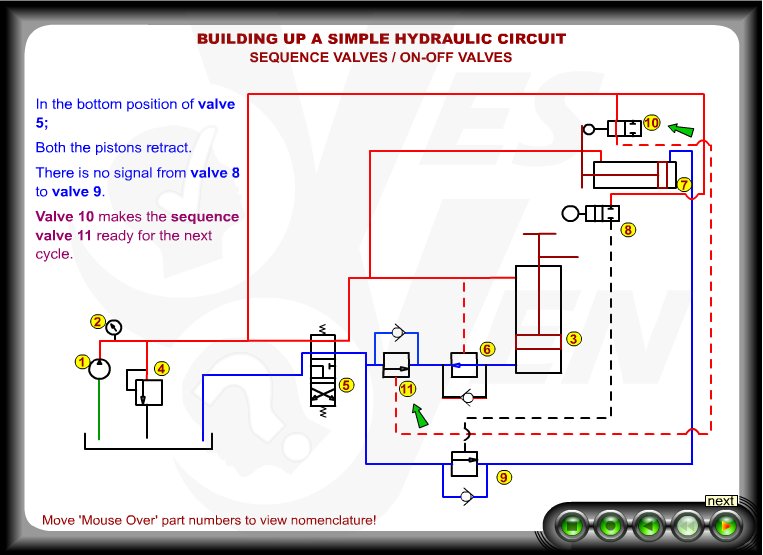

Hydraulic Circuit (snapshot from a hydraulic circuit build-up in the course)

Animated Cut-Sections give a Deep Insight into how Hydraulic Components work.

in ARABIC VERSION

The INDUSTRIAL HYDRAULIC TRAINING course provides a

Intricate, Practical (virtual), Comprehensive Knowledge on the Subject!

OPTIONS for INDUSTRIES / VOCATIONAL TRAINING INSTITUTES / COMMUNITY COLLEGES

Standalone optionUS$349

- For access in multiple systems (one at a time).

Multiple user option10 user - US$1050 50 user - US$1750Unlimited user - US$2100

- For simultaneous access in an organization LMS.

Multiple user option (SCORM)Customized rates based on requirement

- For simultaneous access in SCORM compliant organization LMS.

Online CLOUD hosting by Yes Yen Customized rates based on requirement-

- Features include CUSTOMIZED webpages for user access with the NAME and LOGO of the organization and individual user performance data.

CONTACT US for further details.

*note: Customized logo embedding provided in the above options.

- 1. Hydraulic Basics

- 1.1. Fundamentals

- 1.1.1. Pressure and Pascal's law

- 1.1.2. Hydraulic leverage / mechanical leverage and simple hydraulic press

- 1.1.3. Hydraulic leverage and energy conservation

- 1.1.4. Simple hydraulic circuit

- 1.1.5. Concept of pressure

- 1.1.6. Relevance of flow in hydraulic circuit

- 1.2. Effect of Flow on System Pressure

- 1.2.1. Pressure buildup when flow is blocked

- 1.2.2. Loss of pressure due to flow (friction)

- 1.2.3. Fluid properties effecting friction

- 1.2.4. Laminar and turbulent flow

- 1.2.5. Flow through restriction

- 1.2.6. Flow through an orifice

- 1.2.7. Flow through resistances in series

- 1.2.8. Flow through resistances in parallel

- 1.2.9. Flow through varying cross-sections

- 1.3. Effect of Load on System Pressure

- 1.4. Factors effecting Pump Suction

- 1.5. Effect of Leak in Hydraulic Circuits

- 1.5.1. Circuit without leak

- 1.5.2. Circuit with leak

- 1.6. Reversing Actuator Direction

- 1.7. Flow Control Circuit

- 1.7.1. Meter-in

- 1.7.2. Meter-out

- 2. Hydraulic Components

- 2.1. Hydraulic Pump

- 2.1.1. Gear pumps

- 2.1.2. Lobe pumps

- 2.1.3. Vane pumps

- 2.1.4. Radial piston pumps

- 2.1.5. Axial - in-line - swash plate piston pumps

- 2.1.6. Axial - bent axis piston pumps

- 2.2. Hydraulic Actuator

- 2.2.1. Linear actuators (Cylinders)

- 2.2.1.1. Single-acting cylinders

- 2.2.1.1.1. Ram

- 2.2.1.1.2. Telescopic

- 2.2.1.2. Double-acting cylinders

- 2.2.1.2.1. Differential

- 2.2.1.2.2. Non-differential (double rod)

- 2.2.1.2.3. Telescopic

- 2.2.1.3. Cylinder - cushioning

- 2.2.1.4. Cylinder - stop tube

- 2.2.2. Rotary actuators (Rotary motor)

- 2.2.2.1. Gear motors

- 2.2.2.2. Vane motors

- 2.2.2.3. Axial - in-line - swash plate piston motors

- 2.2.2.4. Axial - bent axis piston motors

- 2.3. Direction Control Valves

- 2.3.1. Check valves

- 2.3.1.1. Simple (inline) check valve

- 2.3.1.2. Right angle check valve

- 2.3.1.3. Restriction check valves

- 2.3.1.4. Pilot operated check valves

- 2.3.2. Number of ways (ports)

- 2.3.2.1. Two-way valves

- 2.3.2.2. Three-way valves

- 2.3.2.3. Four-way valves

- 2.3.3. Number of positions

- 2.3.3.1. Two-position valve

- 2.3.3.2. Three-position valve

- 2.3.4. Methods of actuation

- 2.3.4.1. Manual actuation

- 2.3.4.2. Mechanical actuation

- 2.3.4.3. Electrical actuation

- 2.3.4.4. Pilot control - Hydraulic / Pneumatic actuation

- 2.3.5. Types of valve element

- 2.3.5.1. Poppet valves

- 2.3.5.2. Rotary valves

- 2.3.5.3. Spool valves

- 2.3.5.3.1. Spool center conditions (three-position valves)

- 2.3.5.3.2. Spring offset / Spring centered / No spring

- 2.3.5.3.3. Pilot operation

- 2.4. Servo Valves

- 2.4.1. Electrohydraulic servo valves

- 2.4.1.1. Single-stage valves

- 2.4.1.2. Two-stage pilot-operated valves

- 2.4.1.3. Jet pipe servo valves

- 2.4.1.4. Flapper jet servo valves

- 2.4.2. Mechanical servo valves

- 2.5. Flow Control Valves

- 2.5.1. By-pass type pressure compensation valve

- 2.5.2. Restrictor type pressure compensation valve

- 2.5.3. Pressure & Temperature compensation valve

- 2.6. Pressure Control Valves

- 2.6.1. Relief valves

- 2.6.1.1. Simple relief valves - poppet type

- 2.6.1.2. Simple relief valves - piston type

- 2.6.1.3. Compound relief valves

- 2.6.2. Sequence valves

- 2.6.3. Counterbalance valves

- 2.6.4. Unloading valves

- 2.6.5. Pressure-reducing valves

- 2.7. Miscellaneous

- 2.7.1. Hydraulic piping

- 2.7.1.1. Pipes

- 2.7.1.1.1. Pipe dimensions

- 2.7.1.1.2. Pipe threads

- 2.7.1.1.3. Pipe fittings

- 2.7.1.2. Tubes

- 2.7.1.2.1. Tube dimensions

- 2.7.1.2.2. Flared compression fittings

- 2.7.1.2.3. Flareless compression fittings

- 2.7.1.2.3.1. Ferrule compression fitting

- 2.7.1.2.3.2. Sleeve compression fitting

- 2.7.1.2.3.3. O-ring compression fitting

- 2.7.1.2.4. Straight thread O-ring connector

- 2.7.1.2.5. Flanged fittings

- 2.7.1.3. Flexible hose

- 2.7.2. Hydraulic sealing

- 2.7.2.1. Flange joint seals / gaskets

- 2.7.2.2. O-ring seals

- 2.7.2.3. Lathe-cut seals

- 2.7.2.4. T-ring seals

- 2.7.2.5. Lip seals

- 2.7.2.6. Cup seals

- 2.7.2.7. Piston rings

- 2.7.2.8. Compression packings

- 2.7.2.9. Face seals

- 2.7.3. Accumulators

- 2.7.3.1. Weight loaded accumulators

- 2.7.3.2. Spring loaded accumulators

- 2.7.3.3. Gas charged accumulators

- 2.7.4. Measuring instruments

- 2.7.4.1. Pressure gauges

- 2.7.4.1.1. Bourdon tube gauge

- 2.7.4.1.2. Schrader gauge

- 2.7.4.2. Flow meters

- 3. Building a Simple Hydraulic Circuit

- 3.1. Job to be done

- 3.2. Simple circuit

- 3.3. Introduce pressure gauge

- 3.4. Introduce relief valve

- 3.5. Introduce direction control valve

- 3.6. Simple circuit with more than one job to be done

- 3.6.1. Pressure gauge / Relief valve / Direction control valve / Counter balance valve / Non return valve / On-off valve / Sequence valve / Back pressure valve / Reducing valve / Flow control valve

- 4. GRAPHICAL SYMBOLS

- 4.1. Lines / Fluid storage / Methods of operation / Fixed displacement pumps / Variable displacement pumps / Pressure control valves / Flow control valves / Directional control valves / Proportional valves / Servo valves / Check valves / Deceleration valves / Hydraulic motors / Cylinders / Miscellaneous

- 5. Conventional and Interactive Skill Tests with Evaluation

The INDUSTRIAL HYDRAULIC TRAINING course provides a

Intricate, Practical (virtual), Comprehensive Knowledge on the Subject!

OPTIONS for INDUSTRIES / VOCATIONAL TRAINING INSTITUTES / COMMUNITY COLLEGES

Standalone optionUS$349

- For access in multiple systems (one at a time).

Multiple user option10 user - US$1050 50 user - US$1750Unlimited user - US$2100

- For simultaneous access in an organization LMS.

Multiple user option (SCORM)Customized rates based on requirement

- For simultaneous access in SCORM compliant organization LMS.

Online CLOUD hosting by Yes Yen Customized rates based on requirement-

- Features include CUSTOMIZED webpages for user access with the NAME and LOGO of the organization and individual user performance data.

CONTACT US for further details.

*note: Customized logo embedding provided in the above options.