- PROCESS PLANT OPERATORS

- INDUSTRIAL MAINTENANCE

- COMMUNITY COLLEGES

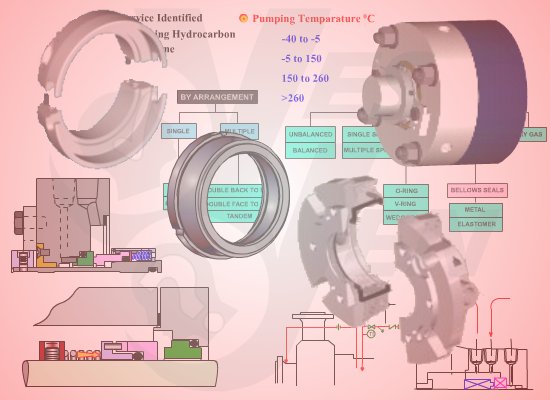

The Mechanical Seal Training Course has been developed to assist in Maintenance and Operation. It covers the various Mechanical Seal Types and explains the Mechanical Seal Working in detail. The training course also includes an API-682 guided Seal Selection tool and a Troubleshooting Guide. The course, designed with extensive Graphics and Animation, gives a virtual Practical exposure on Mechanical Seals.

Click above 'image' for Animated Demo/Guided Tour of the Mechanical Seals

Training Course which focuses on Graphics, Animation and Step-by-Step Learning

MECHANICAL SEALS - A FEW HIGLIGHTS

- Extensive coverage of Seal Designs, Arrangements, etc.

- API - 682, Seal Types, Arrangements and Plans

- 2D / 3D graphics, models and animations

- An Interactive, Seal Selection Procedure tool

- Glossary, Skill tests, Certificate printouts.

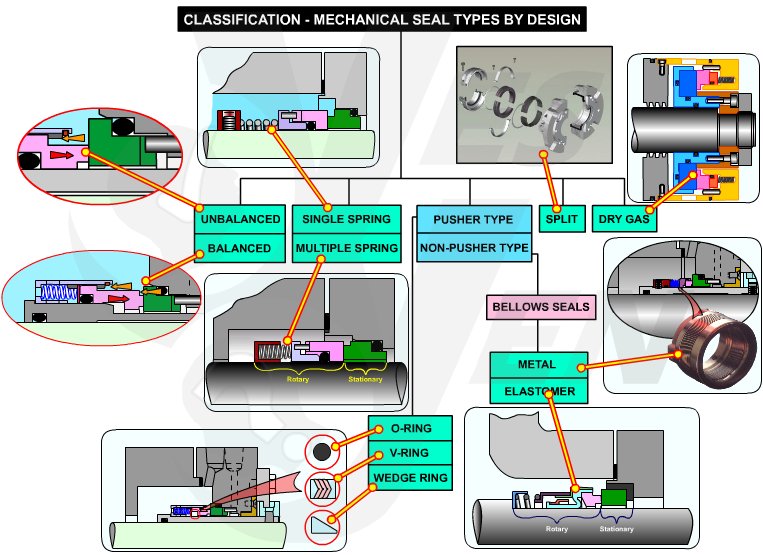

The Mechanical Seal Training Course covers a large range of Seal types like Pusher Seals, Non-Pusher, Cartridge, Split, Double, Tandem, Dry Gas Seals, Spring, Bellow Seals, etc. and provides a detailed Mechanical Seal Classification. The classification provides a clear understanding on the various Mechanical Seal Types and their respective Working Principle. The animations and seal graphics give a clear differentiation among the various seal types and the related requirements for which they are suitable.

Mechanical Seal Types

The primary focus on Mechanical Seal Animation and Graphic helps in very clearly understanding Mechanical Seal Working Principle / Operating Principle. The meticulous multimedia approach gives a virtual description of Mechanical Seal Maintenance Procedures and is sure to be a handy reference for Seal Repair.

The CBT provides a detailed knowledge on Seal Installation, Assembly and Dismantling. Illustration uses both 2D and 3D outputs for a complete understanding. The Mechanical Seal Training Program has a dedicated module to assist in Seal Troubleshooting with a very useful graphical interface. A dedicated module helps to understand the basic criteria followed in Selection of Mechanical Seals for a particular operation and advises on the Seal Plan, Type and arrangement (API 682 guided Seal Selection Procedure).

The Mechanical Seal Graphic has detailed Animated Cut-Sections that gives a virtual knowledge of the internals, which could otherwise be very difficult to understand. The meticulous use of powerful multimedia techniques gives a deep insight into Mechanical Seal Operation. The step-by-step conceived intricate explanations provide a very practical understanding on how Mechanical Seals work...

The MECHANICAL SEALS TRAINING course provides a

Intricate, Practical (virtual), Comprehensive Knowledge on the Subject!

OPTIONS for INDUSTRIES / VOCATIONAL TRAINING INSTITUTES / COMMUNITY COLLEGES

Standalone optionUS$349

- For access in multiple systems (one at a time).

Multiple user option10 user - US$1050 50 user - US$1750Unlimited user - US$2100

- For simultaneous access in an organization LMS.

Multiple user option (SCORM)Customized rates based on requirement

- For simultaneous access in SCORM compliant organization LMS.

Online CLOUD hosting by Yes Yen Customized rates based on requirement-

- Features include CUSTOMIZED webpages for user access with the NAME and LOGO of the organization and individual user performance data.

CONTACT US for further details.

*note: Customized logo embedding provided in the above options.

- 1. Mechanical Seal Fundamentals

- 1.1. Fundamentals of Mechanical Seal Operation

- 1.1.1. Seal requirements

- 1.1.2. Packed Stuffing Box

- 1.1.3. Simple Mechanical Seal

- 1.1.4. Seal Face Lubrication

- 1.1.5. Sealing points

- 1.2. Basic Seal Designs

- 1.2.1. Pusher Seal

- 1.2.2. Non-pusher (Bellow) Seal

- 1.2.3. Pusher seal vs. Non pusher seal

- 1.2.4. API seal types

- 1.3. Variation in basic seal designs

- 1.3.1. Unbalanced Seals

- 1.3.2. Balanced Seals

- 1.3.3. Mixer Seals

- 1.3.4. High Pressure Seals

- 1.3.5. High Speed Seals

- 1.3.6. Dry Gas Seal

- 1.3.7. Split seal

- 1.4. Mechanical Seal Arrangements

- 1.4.1. Inside Seals

- 1.4.2. Outside Seals

- 1.4.3. Double Seals

- 1.4.4. Tandem Seals

- 1.4.5. Cartridge Seals

- 1.4.6. API seal arrangements

- 2. Environmental Controls - Popular Seal Flushing � API Plans

- 2.1. Standard Seal Flush Plan 1

- 2.2. Standard Seal Flush Plan 2

- 2.3. Standard Seal Flush Plan 11

- 2.4. Standard Seal Flush Plan 12

- 2.5. Standard Seal Flush Plan 13

- 2.6. Standard Seal Flush Plan 21

- 2.7. Standard Seal Flush Plan 22

- 2.8. Standard Seal Flush Plan 23

- 2.9. Standard Seal Flush Plan 31

- 2.10. Standard Seal Flush Plan 32

- 2.11. Standard Seal Flush Plan 41

- 2.12. Standard Seal Flush Plan 51

- 2.13. Standard Seal Flush Plan 52

- 2.14. Standard Seal Flush Plan 53

- 2.15. Standard Seal Flush Plan 54

- 2.16. Standard Seal Flush Plan 61

- 2.17. Standard Seal Flush Plan 62

- 3. Seal Installation / Operation / Maintenance

- 3.1. Equipment Checkpoints

- 3.2. Seal Checkpoints

- 3.3. Seal Installation

- 3.4. Environmental Controls Installation

- 3.5. Start-up and operation

- 3.6. Seal Maintenance

- 4. Troubleshooting and Failure Analysis

- 4.1. Full contact Pattern

- 4.2. Coning (Negative Rotation)

- 4.3. Thermal Distortion (Positive Rotation)

- 4.4. Mechanical Distortion – Type: 1

- 4.5. Mechanical Distortion – Type: 2

- 4.6. Mechanical Distortion – Type: 3

- 4.7. Thermally Distressed – Type: 1

- 4.8. Thermally Distressed – Type: 2

- 4.9. Thermally Distressed – Type: 3

- 4.10. High Wear and Grooving

- 4.11. Out of Square Matting Ring

- 4.12. Wide Contact Pattern

- 4.13. Eccentric Contact Pattern

- 5. Glossary and Definition of Seal Terms

- 6. Conventional and Interactive Skill Tests with evaluation

- 7. API-682 (guided) Seal Selection Procedure Tool

The MECHANICAL SEALS TRAINING course provides a

Intricate, Practical (virtual), Comprehensive Knowledge on the Subject!

OPTIONS for INDUSTRIES / VOCATIONAL TRAINING INSTITUTES / COMMUNITY COLLEGES

Standalone optionUS$349

- For access in multiple systems (one at a time).

Multiple user option10 user - US$1050 50 user - US$1750Unlimited user - US$2100

- For simultaneous access in an organization LMS.

Multiple user option (SCORM)Customized rates based on requirement

- For simultaneous access in SCORM compliant organization LMS.

Online CLOUD hosting by Yes Yen Customized rates based on requirement-

- Features include CUSTOMIZED webpages for user access with the NAME and LOGO of the organization and individual user performance data.

CONTACT US for further details.

*note: Customized logo embedding provided in the above options.