- PROCESS PLANT OPERATORS

- INDUSTRIAL MAINTENANCE

- COMMUNITY COLLEGES

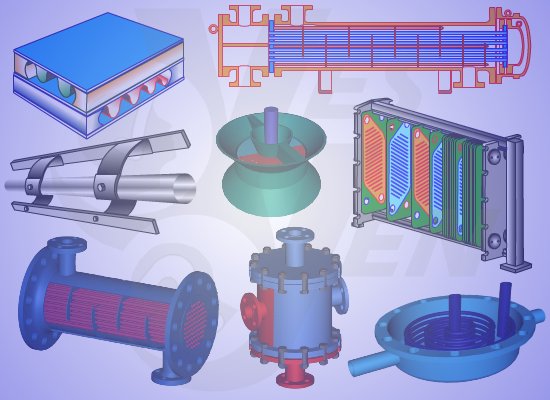

The Training Course on various Heat Exchanger Types has been developed to assist in Heat Exchanger Maintenance, Operation and Repair. The course, designed with extensive Graphics and Animation, gives a virtual Practical exposure on the Heat Exchanger Working Principle and Theory.

Click above 'image' for Animated Demo/Guided Tour of the Heat Exchanger

Training Course which focuses on Graphics, Animation and Step-by-Step Learning

HEAT EXCHANGERS - A FEW HIGLIGHTS

- A large range of Heat Exchangers covered.

- Popular Exchangers like 'Shell and Tube' covered in great detail.

- Extensive 2D / 3D Graphics, Models and Animations.

- A game on TEMA selection! Around 250 Exchangers can be assembled.

- Glossary, Skill tests, Certificate printouts.

The Heat Exchanger Training Course covers a large range of Exchanger Types like Shell & Tube Exchanger (includes TEMA type classification), Air Cooled, Plate & Frame (Plate Exchanger), Spiral, etc.

Detailed Coverage has been provided using extensive Animation on Heat Exchanger Operation and Maintenance aspects of popular Tubular Exchanger Manufacturers Association - TEMA - AES, BEM, AEP, CFU, AKT & AJW - Heat Exchanger Types.

The primary focus on Heat Exchanger Animation and Graphic in the Training Course helps in very clearly understanding Heat Exchanger Operating Principle / Working Principle / Maintenance Procedures. The learning with primary focus on multimedia outputs would definitely be an important aid in Heat Exchanger Repair and related requirements.

The Heat Exchanger Training Program provides a step by step knowledge using sequential interactivity on the basic procedure involved in Heat Exchanger Assembly and Dismantling. The content covers the topic to component level detail.

The Heat Exchanger Graphic includes Animated Cross-Sections at component and equipment level that gives a virtual practical knowledge on the internals, which would otherwise be very difficult to understand by directly observing the equipment. The detailed coverage with the meticulous focus on Multimedia techniques gives a deep insight into How Heat Exchangers work...

The HEAT EXCHANGER TRAINING course provides a

Intricate, Practical (virtual), Comprehensive Knowledge on the Subject!

OPTIONS for INDUSTRIES / VOCATIONAL TRAINING INSTITUTES / COMMUNITY COLLEGES

Standalone optionUS$349

- For access in multiple systems (one at a time).

Multiple user option10 user - US$1050 50 user - US$1750Unlimited user - US$2100

- For simultaneous access in an organization LMS.

Multiple user option (SCORM)Customized rates based on requirement

- For simultaneous access in SCORM compliant organization LMS.

Online CLOUD hosting by Yes Yen Customized rates based on requirement-

- Features include CUSTOMIZED webpages for user access with the NAME and LOGO of the organization and individual user performance data.

CONTACT US for further details.

*note: Customized logo embedding provided in the above options.

- 1. Different Types of Heat Exchangers

- 1.1. Introduction

- 1.2. Shell and Tube Heat Exchanger

- 1.3. Air Cooled Heat Exchanger

- 1.4. Spiral Plate Heat Exchanger

- 1.5. Plate and Frame Heat Exchanger

- 1.6. Plate and Fin Heat Exchanger

- 1.7. Evaporative Cooled Heat Exchanger

- 1.8. Spiral Tube Heat Exchanger

- 1.9. Double Pipe Heat Exchanger

- 1.10. Bayonet Heat Exchanger

- 1.11. Patterned Plate Heat Exchanger

- 1.12. Mechanically aided (Scraped Surface Exchanger & Thin Film Exchanger)

- 1.13. Jacketed Vessels

- 1.14. Fired Heaters

- 1.15. Regenerative Heat Exchanger

- 2. Detailed Description of Popular Shell and Tube Exchangers (includes Breech-Lock Exchangers)

- 2.1. Principle of operation of Shell and Tube Heat Exchangers

- 2.1.1. Fixed-Tube-Sheet Heat Exchanger (BEM)

- 2.1.2. U – Tube Heat Exchanger (CFU)

- 2.1.3. Packed-Lantern-Ring Heat Exchanger (AJW)

- 2.1.4. Outside Packed Floating Head Exchanger (AEP)

- 2.1.5. Internal Floating Head Exchanger (AES)

- 2.1.6. Kettle type - Pull-Through Floating Head Exchanger (Reboiler / AKT)

- 2.2. Construction

- 2.2.1. Exploded views of Fixed-Tube-Sheet Heat Exchanger

- 2.2.2. Exploded views of U – Tube Heat Exchanger

- 2.2.3. Exploded views of Packed-Lantern-Ring Heat Exchanger

- 2.2.4. Exploded views of Outside Packed Floating Head Exchanger

- 2.2.5. Exploded views of Internal Floating Head Exchanger

- 2.2.6. Exploded views of Pull-Through Floating Head Exchanger

- 2.3. Hydraulic Pressure Testing and related Maintenance details

- 2.3.1. Fixed-Tube-Sheet Heat Exchanger

- 2.3.2. U – Tube Heat Exchanger

- 2.3.3. Packed-Lantern-Ring Heat Exchanger

- 2.3.4. Outside Packed Floating Head Exchanger

- 2.3.5. Internal Floating Head Exchanger

- 2.3.6. Pull-Through Floating Head

- 2.4. Tube-Side construction

- 2.4.1. Tube-Side Header

- 2.4.2. Bonnet

- 2.4.3. Channel

- 2.4.4. High Pressure Closures

- 2.4.5. Tube-Side Passes

- 2.4.6. Integrally Finned Tubes

- 2.4.7. Tube Layout

- 2.4.8. Tube Sheet

- 2.4.9. Rolled Tube Joints

- 2.4.10. Welded Tube Joints

- 2.4.11. Tubes and Tolerances

- 2.5. Shell-Side Construction

- 2.5.1. Shell Sizes

- 2.5.2. Shell Side Arrangements

- 2.6. Baffles and Tube Bundles

- 2.6.1. Segmental Baffles

- 2.6.2. Tie Rods and Spacers

- 2.6.3. Impingement Baffles

- 2.6.4. Vapor Distribution

- 2.6.5. Tube-Bundle Bypassing

- 2.6.6. Longitudinal Baffles

- 2.7. Breech-Lock Exchangers (High Pressure Exchangers)

- 2.7.1. Principle of Operation

- 2.7.2. Construction

- 2.7.3. Dismantling and Assembly Procedure

- 3. Air Cooled Exchangers

- 3.1.Operation – Flow Path across the exchanger

- 3.2.Exploded views

- 3.3.Maintenance details

- 4. Plate and Frame Exchangers

- 4.1.Operation – Flow Path across the exchanger

- 4.2.Exploded views

- 5. TEMA UNDERSTANDING

- 5.1. Selection and Game on TEMA types

- 5.1.1. Front End Stationary Head Type

- 5.1.1.1. Channel and Removable Cover

- 5.1.1.2. Bonnet (Integral Cover)

- 5.1.1.3. Channel integral with Tube-Sheet and Removable Cover

- 5.1.1.4. Channel integral with Shell and Removable Cover

- 5.1.1.5. Special High Pressure Closure

- 5.1.2. Shell Types

- 5.1.2.1. One Pass Shell

- 5.1.2.2. Two Pass Shell with Longitudinal Baffle

- 5.1.2.3. Split Flow

- 5.1.2.4. Double Split Flow

- 5.1.2.5. Divided Flow

- 5.1.2.6. Kettle type Re-boiler

- 5.1.2.7. Cross Flow

- 5.1.3. Rear End Head Type

- 5.1.3.1. Fixed Tube type – 'A' Stationary Head

- 5.1.3.2. Fixed Tube type – 'B' Stationary Head

- 5.1.3.3. Fixed Tube type – 'N' Stationary Head

- 5.1.3.4. Guided Packed Floating Head

- 5.1.3.5. Out side Packed Floating Head

- 5.1.3.6. Floating Head with Backing Device

- 5.1.3.7. Pull-Through Floating Head

- 5.1.3.8. U – Tube Bundle

- 5.1.3.9. Externally Sealed Floating Head

- 5.2. Skill Test

- 6. Glossary of Technical Terms

- 7. Conventional and Interactive Skill Tests with evaluation

The HEAT EXCHANGER TRAINING course provides a

Intricate, Practical (virtual), Comprehensive Knowledge on the Subject!

OPTIONS for INDUSTRIES / VOCATIONAL TRAINING INSTITUTES / COMMUNITY COLLEGES

Standalone optionUS$349

- For access in multiple systems (one at a time).

Multiple user option10 user - US$1050 50 user - US$1750Unlimited user - US$2100

- For simultaneous access in an organization LMS.

Multiple user option (SCORM)Customized rates based on requirement

- For simultaneous access in SCORM compliant organization LMS.

Online CLOUD hosting by Yes Yen Customized rates based on requirement-

- Features include CUSTOMIZED webpages for user access with the NAME and LOGO of the organization and individual user performance data.

CONTACT US for further details.

*note: Customized logo embedding provided in the above options.