- PROCESS PLANT OPERATORS

- INDUSTRIAL MAINTENANCE

- COMMUNITY COLLEGES

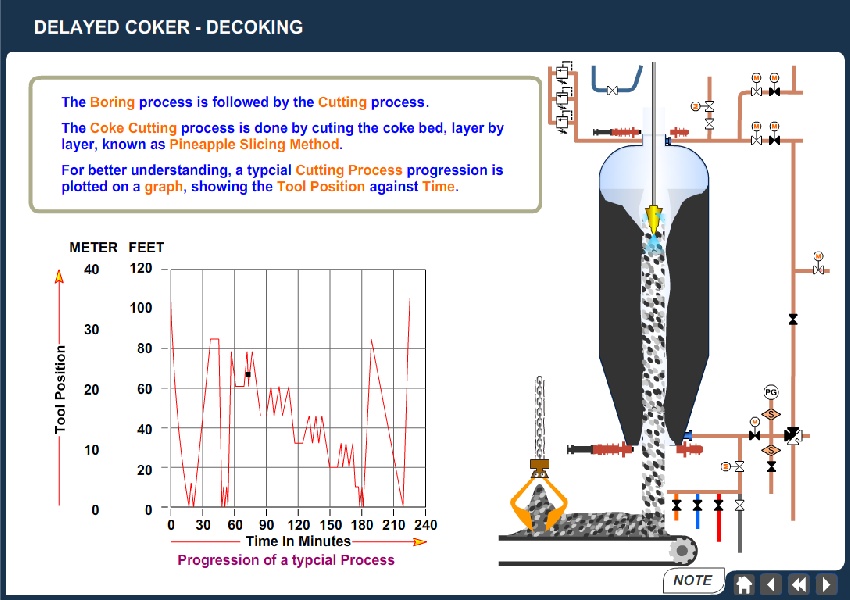

In a Refinery the Delayed Coker Unit Process is a type of Coking Process where residual oil from vacuum distillation column is converted to low molecular weight hydrocarbon gases, naphtha, etc. In the Delayed Coking Process, the residual oil is heated to its cracking temperature in a furnace. The heating in the Delayed Coker Unit Operation, cracks the long chain heavy carbon and hydrogen molecules to facilitate the coking process.

In the Training Module on the Delayed Coker Unit Process, a typical Coking and Decoking Process Cycle is Explained with detailed Animation in a Step by Step Sequence.

Figure above is a snapshot from the Delayed Coking Process Training module

The procedure described includes the sequential operation of the various valves, little steam, big steam, water injection, quenching, slow water, fast water and all related processes involved in the Coking and Decoking Cycle.

We can develop similar content CUSTOMIZED to SPECIFIC Flow Diagrams / P & I Diagrams / Process Flow / Equipment Working, etc for REFINERIES & PROCESS INDUSTRIES.

Process Industries / Refineries are requested to contact us for a FULL DEMO of the above Training Module on "Delayed Coker Unit", using the below form.