- PROCESS PLANT OPERATORS

- INDUSTRIAL MAINTENANCE

- COMMUNITY COLLEGES

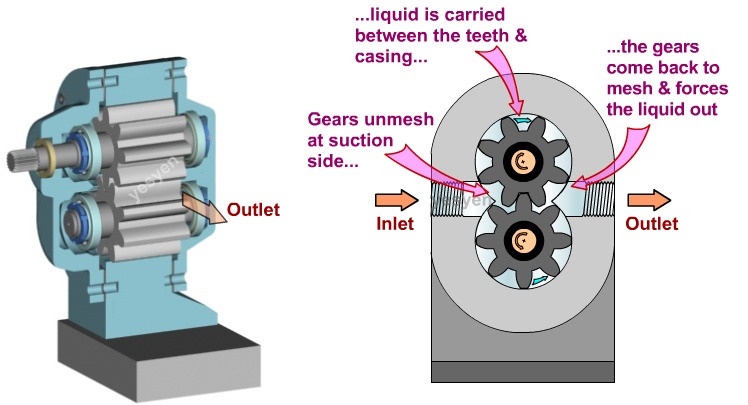

GEAR PUMP WORKING PRINCIPLE -

ANIMATION VIDEO

A Gear Pump is a rotary type of positive displacement pump. The gear pump working principle involves the rotary action of two gear toothed rotors which

- unmeshes at the suction end thus drawing in liquid

- carries liquid along the gear teeth and

- meshes at discharge end thus forcing the liquid out against discharge line pressure.

Gear pumps are primarily of the external gear and internal gear type. External gear pumps use straight spur type gears or helical type gears for their working. A typical representation of an external - spur type gear pump is shown above.

The gear pump working animation video below describes the working principle of the spur type gear pump, which is more common.

In the gear pump, one of the rotors receives drive from an external source and directly transmits the drive to the other rotor. Since the rotors make direct contact they are not preferred for pumping suspended solids. They are widely used for lubrication and hydraulic systems.

Gear Pump Working Animation Video

(The above video that briefly explains the gear pump working is a SIMPLIFIED extract [for

video] from the Positive Displacement Pump Training Course listed in the 'Product' page)

For a Detailed Training on Positive Displacement Pumps

(Rotary and Reciprocating)

with Extensive Animations and Graphics,

which give a Practical Understanding probably to a level

never achieved before, avail the

TRAINING COURSE ON POSITIVE DISPLACEMENT PUMPS