- PROCESS PLANT OPERATORS

- INDUSTRIAL MAINTENANCE

- COMMUNITY COLLEGES

Gain the confidence of handling any Tough Alignment Challenges

ONE DAY INTENSIVE ALIGNMENT COURSE

Covering Scientific Alignment Methods and Procedure

Last saturday of every month

How is the alignment job done in your plant, by proven/tested alignment procedure and methods or by trial and error?

For the above question, most supervisors and engineers would immediately respond, "We always/only use proven, tested alignment methods / techniques / procedure and our technicians are well trained to handle any difficult alignment requirement."

But of my 40 years' experience, I like to comment, "In my Shaft Alignment training classes, I have seen supervisors/engineers use different formulas and alignment methods, mostly not knowing the basic alignment procedure concepts. The technicians mostly use 'trial and error' practice; and frequently tells the boss, "Rotating Equipment Shaft Alignment sometimes takes huge unpredicted time".

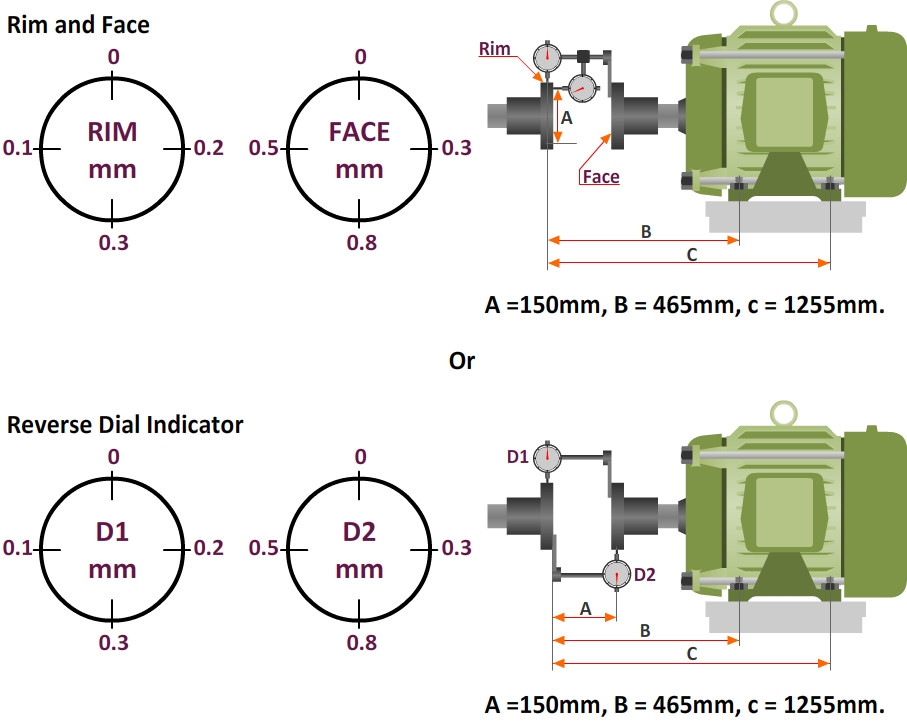

If you disagree with the above statement, well, shall we try the following challenge? For the following situation, what are the corrections needed at motor feet for Alignment?

Are you confident of your answer?

Who did the calculations, supervisors or technicians?

Was the calculations confusion free for both supervisor and technician?

In reality, the supervisors/engineers have many responsibilities/activities besides the alignment training and practice requirements. In such tight situation, is the respective supervisor/engineer available to clear calculation doubts that arises for the performing technician on the alignment method?

We suggest the following one day classroom Alignment Training Class on Rotating Equipment Alignment Practice:

The Rotating Equipment (Machine / Shaft / Coupling) Alignment Training Course will cover several alignment methods/techniques like Straight Edge, Rim Face Alignment and Reverse Dial Indicator Alignment procedure.

An important understanding required is the confident use of Dial Gauges. This topic is covered in detail using Dial Gauge Animation / Working with step by step procedure. The class explains the working of a Dial Gauge and will provide an in-depth understanding of taking and interpreting readings for Dial Gauge Alignment.

The training class will help in very clearly understanding the various Alignment methods and Procedures. The Reverse Dial Indicator (Peripheral) Alignment Procedure, which is also the principle behind the Laser Alignment technique, is dealt in explicit detail.

The Training Class, Course Takeaway includes:

- Gaining the Knowledge & Confidence for handling any Tough Alignment Challenges

- Reference material

- Certificate

Director,

Yes Yen GraphiTech

ONE DAY INTENSIVE ALIGNMENT COURSE

(Last saturday of every month)

Course Fee: Rs. 3000 + GST/- (Rs. Three Thousand + GST)

Completion certificate will be awarded along with a quick reference handout.

Book in advance.

Avail discounts for bulk booking.

Venkateshwara Nagar, Kottivakkam,

Chennai 600 041, Tamil Nadu

India

| Ph: | +91 44 24514788 +91 9176238863 +91 9444009613 +91 9962128043 |

Please enter your details and date preference in the "registration form" below and we shall contact you on class availability and related details:

Registration Form

Meanwhile you can consider the online web based training (WBT) or Computer Based Training (CBT) options, which offers a highly practical oriented learning.

Thank you for the cooperation and please contact us for any query.