- PROCESS PLANT OPERATORS

- INDUSTRIAL MAINTENANCE

- COMMUNITY COLLEGES

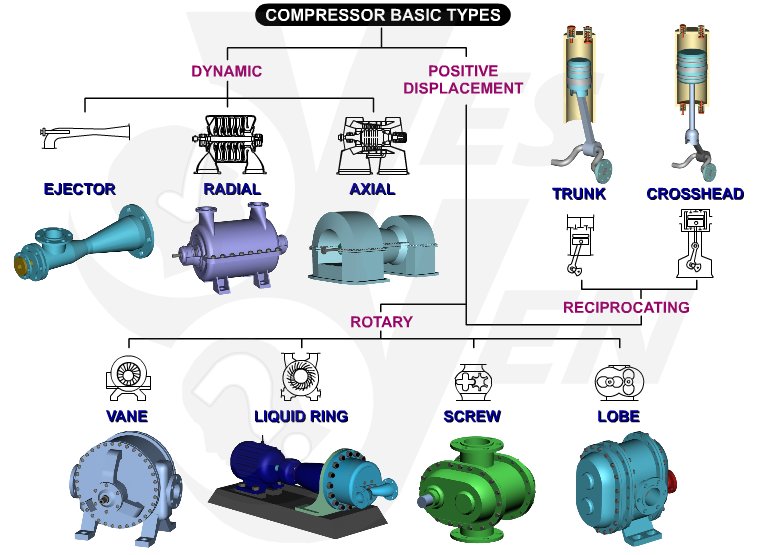

Compressors are a major category of equipment used in industries. Compressors are used to compress gas or air for various process requirements. Different Compressor Types are used to meet specific requirements based on their working principle.

Depiction above shows Compressor Types based on their Classification as Dynamic and Positive Displacement Compressors. Positive Displacement Compressors are further classified into Rotary and Reciprocating Compressors.

Compressors are broadly classified based on the methods of compression used. The methods of compression used and related compressor types are:

- Trap consecutive volumes of gas in an enclosure, reduce the volume thus increasing the pressure, and push the compressed gas out of the enclosure. e.g. Reciprocating, Sliding Vane and Liquid Ring Compressor types

- Trap consecutive volumes of gas in an enclosure, carry it without volume change to the discharge opening, compress the gas by backflow from the discharge system and push the compressed gas out of the enclosure. e.g. Screw and Lobe Compressor types

- Positive Displacement compressors use the above two methods of compression.

- The mechanical action of rapidly rotating rotors impart velocity and pressure to the gas and compress it. (Velocity is further converted to pressure in diffusers) Dynamic compressors - Radial and Axial Compressor types

- Gas is entrained in a high velocity jet of the same gas or another gas (usually steam). The high velocity of the mixture is converted to pressure in a diffuser. Dynamic compressors - Ejector Compressor type

A FREE Description of the various Compressor Types is provided in the tutorial listed below.

VIEW / DOWNLOAD graphically described COMPRESSOR TYPE CLASSIFICATION / GAME

with Extensive Animations and Graphics,

which give a Practical Understanding probably to a level never achieved before avail the

TRAINING COURSE ON COMPRESSORS