- PROCESS PLANT OPERATORS

- INDUSTRIAL MAINTENANCE

- COMMUNITY COLLEGES

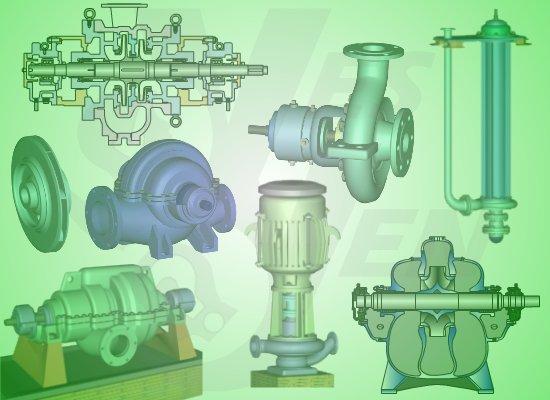

The Centrifugal Pump Training Course has been developed to assist in Maintenance and Operation. It covers the various API 610 - Centrifugal Pump Types and covers the Centrifugal Pump Working Principle and Theory. The course also includes a detailed Pump Troubleshooting Guide. The course, designed with extensive Graphics and Animation, gives a virtual Practical exposure on Centrifugal Pumps.

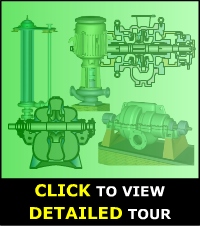

Click above 'image' for Animated Demo/Guided Tour of the Centrifugal Pump

Training Course which focuses on Graphics, Animation and Step-by-Step Learning

CENTRIFUGAL PUMPS - A FEW HIGLIGHTS

- Basics & Principles of Centrifugal Pump - Working

- Detailed understanding of API - 610 types of pumps

- Extensive 2D / 3D Graphics, Models and Animations

- An Interactive, Graphically supported Troubleshooting Guide

- Glossary, Games on Component Assembly, Skill tests, Certificate printouts...

The Centrifugal Pump Training Course covers a large range of Pump Types (includes API 610 type - Overhung Pumps, Between Bearing Pumps and Vertical Suspended Pumps). The course provides a detailed Pump Classification based on Construction and the various types like Radial, Mixed and Axial.

The primary focus on Centrifugal Pump Animation and Graphic helps in very clearly understanding Centrifugal Pump Maintenance Procedures & Centrifugal Pump Operating Principle / Working Principle like Pump Cavitation, Performance Curves, NPSH, Suction Head, Discharge Head, Priming, etc. The focus on multimedia outputs is sure to give an understanding that aids in Pump Repair and related requirements. All the topics like Pump Performance Characteristics, etc are covered using extensive Animations.

The CBT provides detailed knowledge on Pump Assembly and Dismantling. Both 2D and 3D outputs give a very comprehensive understanding on the subject.

The Centrifugal Pump Training Program has a dedicated module to assist in Pump Troubleshooting, which has graphical / animated explanations to give a very clear understanding. A glossary covers various important terms related to the troubleshooting and Centrifugal Pump Operation aspects that are explained in detail towards enabling trouble free Performance.

The Pump Graphic includes Animated Cut-Sections that give a virtual practical knowledge on the internals, which could otherwise be very difficult to understand by directly observing the equipment. The detailed training with the meticulous focus on Multimedia Outputs very clearly explains the Centrifugal Pump Working Principle and gives a Deep Insight into How Centrifugal Pumps work...

The CENTRIFUGAL PUMPS TRAINING course provides a

Intricate, Practical (virtual), Comprehensive Knowledge on the Subject!

OPTIONS for INDUSTRIES / VOCATIONAL TRAINING INSTITUTES / COMMUNITY COLLEGES

Standalone optionUS$349

- For access in multiple systems (one at a time).

Multiple user option10 user - US$1050 50 user - US$1750Unlimited user - US$2100

- For simultaneous access in an organization LMS.

Multiple user option (SCORM)Customized rates based on requirement

- For simultaneous access in SCORM compliant organization LMS.

Online CLOUD hosting by Yes Yen Customized rates based on requirement-

- Features include CUSTOMIZED webpages for user access with the NAME and LOGO of the organization and individual user performance data.

CONTACT US for further details.

*note: Customized logo embedding provided in the above options.

- 1. Introduction

- 2. Pump classification

- 2.1. Centrifugal pumps

- 2.2. Mixed flow pumps

- 2.3. Axial flow pumps

- 2.4. Type and Construction based on:

- 2.4.1. Suction design

- 2.4.1.1. Single

- 2.4.1.2. Double

- 2.4.2. No. of stages

- 2.4.2.1. Single

- 2.4.2.2. Multistage

- 2.4.3. Guide vanes

- 2.4.3.1. Volute

- 2.4.3.2. Turbine

- 2.4.4. Casing construction

- 2.4.4.1. Radially Split

- 2.4.4.2. Axially Split

- 2.4.4.3. Double Casing

- 2.4.5. Impeller shrouds

- 2.4.5.1. Open

- 2.4.5.2. Partially Open

- 2.4.5.3. Closed

- 2.4.6. Shaft position

- 2.4.6.1. Horizontal

- 2.4.6.2. Vertical

- 3. Centrifugal Pump Basics

- 3.1. Principle of operation

- 3.2. Pressure concepts

- 3.3. Hydraulics - a few basics

- 3.4. Vapor pressure

- 3.5. Pump Cavitation

- 3.6. Pump NPSH - Net positive suction head

- 3.7. Pump curves / Pump Performance curves / Pump characteristic curves

- 4. API - 610 Types and features

- 4.1. Overhung

- 4.1.1. Flexibly Coupled

- 4.1.1.1. Horizontal

- 4.1.1.1.1. Foot Mounted : OH1

- 4.1.1.1.2. Center line Mounted : OH2

- 4.1.1.2. Vertical

- 4.1.1.2.1. In-line Bearing Frame : OH3

- 4.1.2. Rigidly Coupled

- 4.1.2.1. Vertical

- 4.1.2.1.1. In-line : OH4

- 4.1.2.2. High Speed Integral Gear : OH5

- 4.2. Between Bearing

- 4.2.1. 1st and 2nd Stage

- 4.2.1.1. Axially Split : BB1

- 4.2.1.2. Radially Split : BB2

- 4.2.2. Multistage

- 4.2.2.1. Axially Split : BB3

- 4.2.2.2. Radially Split

- 4.2.2.2.1. Single Casing : BB4

- 4.2.2.2.2. Double Casing : BB5

- 4.3. Vertical Suspended

- 4.3.1. Single Casing

- 4.3.1.1. Discharge through Column

- 4.3.1.1.1. Diffuser : VS1

- 4.3.1.1.2. Volute : VS2

- 4.3.1.1.3. Axial Flow : VS3

- 4.3.1.2. Separate Discharge (Sump)

- 4.3.1.2.1. Line Shaft : VS4

- 4.3.1.2.2. Cantilever : VS5

- 4.3.2. Double Casing

- 4.3.2.1. Diffuser : VS6

- 4.3.2.2. Volute : VS7

- 4.4. Wear ring running clearances

- 4.5. Mechanical seal types / arrangement / plans

- 4.6. Cooling water piping

- 4.7. Lube oil system

- 5. Conventional and Interactive Skill Tests with evaluation

- 6. Games - Component assembly

- 6.1. Overhung pump - OH

- 6.2. Between bearing pump - BB

- 6.3. Vertical suspended pump - VS

- 7. Technical Glossary

- 8. Troubleshooting Guide

- This troubleshooting guide, besides being a training package also serves as a day-to-day reference for Operation and Maintenance. Defective pumps will express one or more of the indicated symptoms of failure or deviation of normal operation. This Operation and Maintenance solution package attempts to bring out the root-causes (System/ Operation / Mechanical troubles) by selecting the symptoms that the subject pump is exhibiting

- • Failure or deviation symptoms

- ο Pump does not deliver

- ο Insufficient capacity delivered

- ο Insufficient discharge pressure developed

- ο Pump loses prime after starting

- ο Pump requires excessive power

- ο Stuffing box / mechanical seal leak excessively

- ο Packing / mechanical seal has short life

- ο Pump vibrates or noisy

- ο Bearing have short life

- ο Pump overheats and seizes

- • Around 45 specific root-causes have been identified similar to the few listed below:

- ο Pump not primed

- ο Suction lift too high

- ο Insufficient margin between suction pressure and vapor pressure

- ο Total head required by process lower than pump design

- ο Specific gravity of liquid different from design

- ο Operation at very low capacity

- ο Parallel operation of pumps unsuitable for such operation

- ο Misalignment

- ο Bearings worn out

- ο Wearing rings worn out

- ο Rotor out of balance causing vibration

- ο Improper selection, fitting or usage of mechanical seal

- ο Lack of lubrication

- • And this guide stands out exclusively with its enhanced graphical explanation of the root-causes, which includes interactivity and extensive animation.

- • The learner / user is well guided by a series of questions, which helps him to accurately pinpoint the root cause.

- • A brief troubleshooting module on mechanical seal is also included.

- • The user can avail printouts of the observed failure symptoms and related root-cause for record.

- • From the glossary the learner / user can avail a good understanding on pump related technical terms such as: Affinity laws for pump performance, Air entrapment, Air leak, Air pocket, Bearing defects, Bent shaft, Capacity, Cavitation, Direction of rotation, Foot valve, Foundation, Gland packing, Hydraulic imbalance, Imbalance, Impeller defect, Impeller improper, Internal rubbing, Lubrication, Mechanical seal, Misalignment, NPSH and related discussions, Parallel operation, Priming, Pump head, Pump performance curves, Pump suction, Shaft sleeve, Specific gravity, Speed low, Stuffing box, Suction lift, System resistance curve, Thrust, Vapor pressure, Vapor pressure and cavitation, Vibration, Viscosity and Wear ring.

- Above indicated topics are supported with graphical depiction and animation besides textual description.

The CENTRIFUGAL PUMPS TRAINING course provides a

Intricate, Practical (virtual), Comprehensive Knowledge on the Subject!

OPTIONS for INDUSTRIES / VOCATIONAL TRAINING INSTITUTES / COMMUNITY COLLEGES

Standalone optionUS$349

- For access in multiple systems (one at a time).

Multiple user option10 user - US$1050 50 user - US$1750Unlimited user - US$2100

- For simultaneous access in an organization LMS.

Multiple user option (SCORM)Customized rates based on requirement

- For simultaneous access in SCORM compliant organization LMS.

Online CLOUD hosting by Yes Yen Customized rates based on requirement-

- Features include CUSTOMIZED webpages for user access with the NAME and LOGO of the organization and individual user performance data.

CONTACT US for further details.

*note: Customized logo embedding provided in the above options.